5 Gallon Smart Foam Unit

FI-5N-SM-YL

- Drop-shipped from FOAMit. Please allow 1-2 days for processing.

- In stock

- Inventory on the way

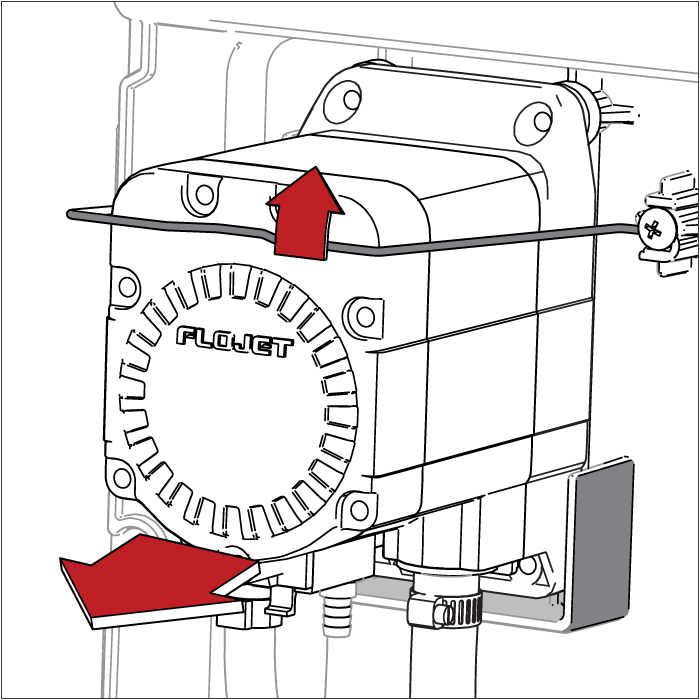

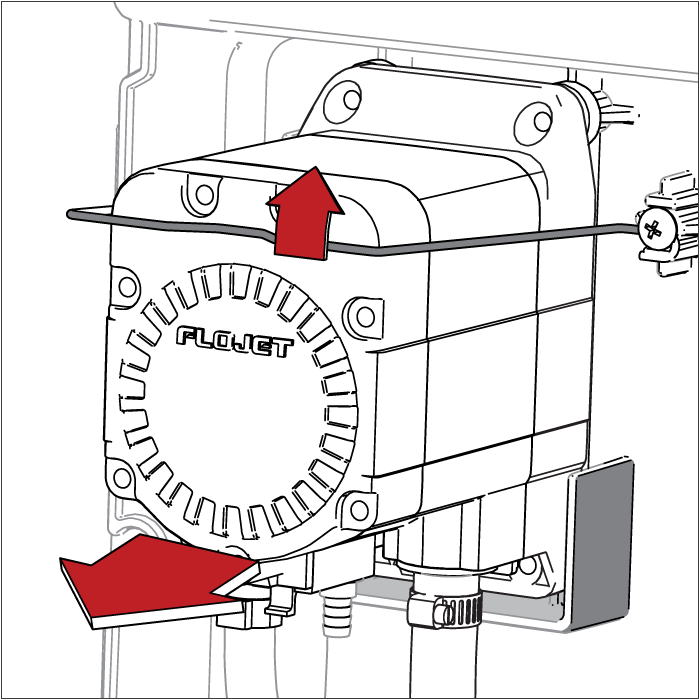

The 5 Gallon Smart Foam Unit is a technologically advanced cleaning tool that is safer to use and maintain than traditional models. It features user-friendly controls to minimize chemical exposure and maximize control. The unit is easy to use, with a comfortable handle and wand, and draws from pre-mixed solution using compressed air. It also features a hinged back plate for easy access to components, a quick-change pump, and a natural color tank for easy visibility of product levels.

- Safer to store and maintain

- Protects user and surroundings from chemical exposure in the event of a fall or accident

- Gives you more control and flexibility

- Easy ON/OFF operation

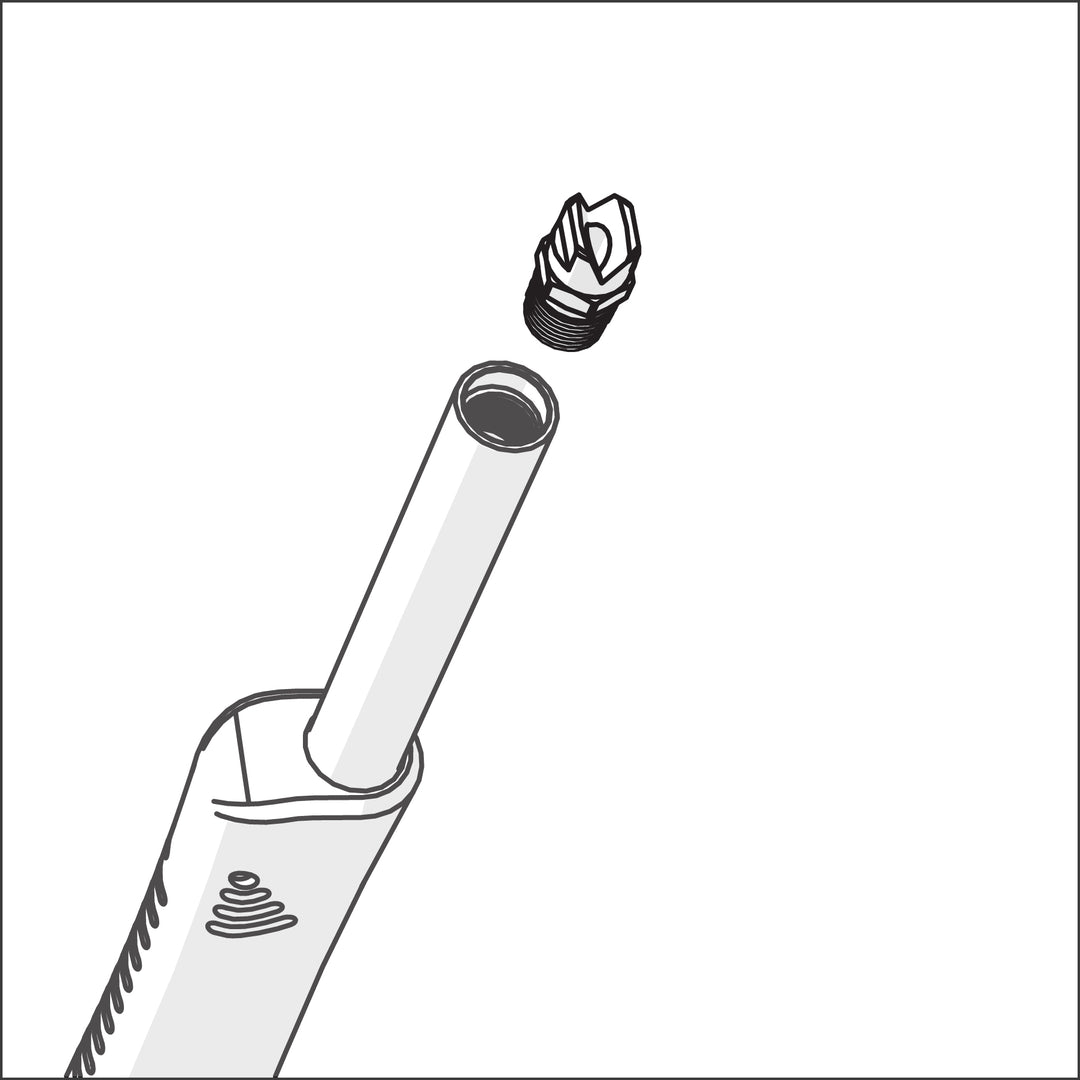

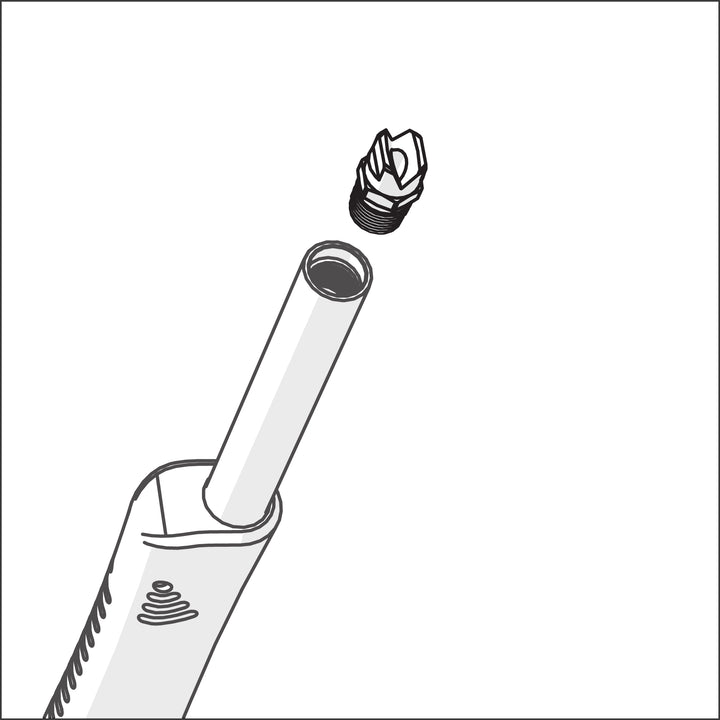

- Handle and wand are tough but lightweight, with fan tip and built-in zero tip

Power type: Compressed air

Chemical pickup type: Draws from a pre-mixed solution

Number of products the unit can draw from: One Product

Capacity: 5 gallons (18.93 liters)

Discharge hose: 20 ft. (6 m) bonded hose, with 5/8 in. (15.9 mm) and 1/4 in. (6.4 mm) inside diameters

Discharge wand: Ultra high molecular weight (UHMW) polyethylene handle and wand, with 65˚ fan tip and built-in zero tip

Output distance: 8-12 ft. (2.4-3.7 m)

Output volume: WITH ZERO TIP: 20-32 gal/min (75-121 l/min) of foam, WITH FAN TIP: 20-32 gal/min (75-121 l/min) of foam

Flow Rate: 2 gal/min (7.6 l/min)

Wheel type: Two 3 inch non-marking wheels

Compressed air requirements: 40-80 psi (3-5 bar) with 5-8 cfm (141-227 l/min)

Liquid temperature range: 40-100˚F (4.4-37˚C)

Chemical compatibility: Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

Choose a pump seal material that is compatible with the chemicals you will use. Chemical incompatibility can cause accelerated wear and equipment failure that is not covered by warranty, so it's important to do your research.

- Consult the safety data sheet (SDS) for your chemical to learn about the ingredients.

- Use a chemical compatibility database (like this one: https://www.coleparmer.com/Chemical-Resistance) to look up the ingredients and find material compatibility info.

- Note that the concentration of chemicals makes a big difference in compatibility. Think about whether the chemical you use will be in a pre-diluted or concentrated form when it is used in the equipment.

- If you need help, ask your chemical manufacturer. Or, send your SDS to techsupport@foamit.com and they can help.